Wood transport: Pierre Geyer and his Arocs 3363

Vehicle & Technology

Pierre Geyer is self-employed and earns his money with an Arocs 3363. To do that he has to get up early and be fast.

Manoeuvring the Arocs with its long load through the forest requires a lot of skill.

The fully-loaded log transporter rolls down the forest road in EcoRoll mode. Pierre Geyer sits at the wheel, completely relaxed. Thanks to its activated cruise control, the three-axle Arocs 3363 seems to drive all on its own. The 46 year-old has been transporting wood for more than half of his life and has been self-employed for ten years. He knows the woods of the Central Vosges like the back of his hand. To the south-west of his location, Wangenbourg-Engenthal, a village on the D 218 road, the Domaniale d'Engenthal forest stretches into the distance whilst the Domaniale de la Mossig forest lies to the east. So Pierre usually doesn't have far to go to reach the loading points.

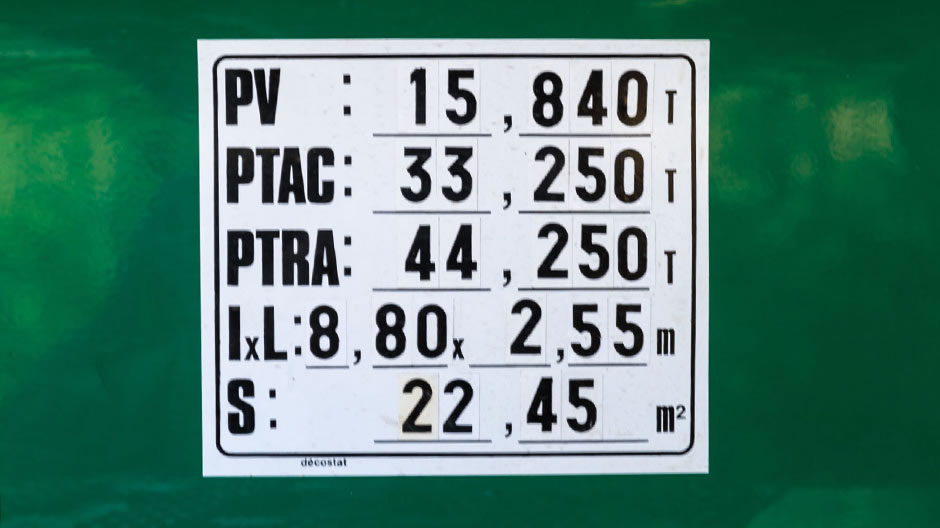

"In my job, material is put through its paces: there are many inclines and the forest tracks are not in a good condition," he says. That is why, ten years ago, Geyer bought an Actros as a tractor unit with which he has covered a total of 772,000 kilometres. "And all that with the original engine and the original clutch," he stresses. Pierre Geyer was so satisfied with his Mercedes-Benz that he definitely wanted to buy another vehicle of the same brand. Even if that meant waiting patiently for eighteen months until the new Arocs with a top engine output of 460 kW had also been approved in France. Once it had been thoroughly reworked, he was able to continue using the loglift Hiab crane from the old tractor unit with the Arocs 3363 – and the self-steering trailer, too.

Pierre knew exactly what sort of equipment he wanted on the new tractor unit. It should have a window on the rear of the cab, a fridge, a reversing camera and above all a catwalk above the wheel arch on the driver's side which would give him access to the loading crane behind the cab without him having to put one foot on the ground. "The most important thing is to lose as little time as possible," he explains whilst he quickly grasps the 18 metre-long logs with the crane's jaws and lowers them gently onto the trailer. "A high engine output is necessary for the same reason, so that the heavily loaded tractor unit can quickly climb the many hills in the Vosges region."

Pierre's main customer is the Siat Braun sawmill in Urmatt. The mill sends him orders on to his tablet computer with exact specifications regarding the volume of wood that has to be loaded up at the different loading points in the forest. The amounts are anything between 2 and 500 cubic metres. The loading points are within a radius of 100 kilometres around his location. In exceptional cases he may drive 200 kilometres.

Because the orders are priced according to volume, whereby the tariff varies according to the length of the logs, Pierre Geyer is always in a hurry: whilst loading with the crane, when driving and when unloading at the sawmill. That is why he usually begins his working day at 4 in the morning. "If you have to go to Strasbourg, you stand in traffic jams from 7.30 a.m. onwards," he says. "Luckily, I've always been an early riser."

Photos: Hans Müller

Comment

Please log in to post a comment.

6 comments

Proficiat van het nadenken bij de constructie. Veel werkplezier met de AROCS 3363 . Ik hoop hem ééns te mogen zien werken en rijden .

Proficiat Pierre Geyer en veel succes .

Proficiat van het nadenken bij de constructie. Veel werkplezier met de AROCS 3363 . Ik hoop hem ééns te mogen zien werken en rijden .

Proficiat Pierre Geyer en veel succes .