Recovery: the Arocs 4451 at Pappas Eugendorf

Vehicle & Technology

If a truck breaks down around Salzburg, Alex Kircher and Werner Huber are on-hand to help with their tow truck. The Arocs 4451 AK 8x6/4 with turbo retarder clutch (TRC) helps them solve any problem.

Werner Huber (R) takes notes on the way to the next job, while Axel Kircher drives the Arocs.

An accident on the Austrian A10 motorway near Pfarrwerfen, a 40-tonne truck which has slid into the barrier of the central reservation near Salzburg city centre, or a damaged truck to be recovered from a forest track high up in Ebenau – it doesn’t take long before Alex Kircher and Werner Huber’s respective phones start to ring. The two specialists from Pappas Eugendorf then set out in their brand-new Arocs 4451 AK 8x6/4 recovery vehicle with turbo retarder clutch to try and recover what can be recovered.

Today is another such example: a truck with a brake system malfunction needs recovering from the A1 near Salzburg-Kasern and then following on from that, there’s a touring coach stranded with engine troubles on the A10. Kircher and Huber often turn up at accident scenes at the same time as the fire service, police and paramedics. They don’t just ensure the recovery of damaged vehicles, the collection and removal of pieces from the wreckage, or the recovery and transfer of the vehicle’s load to another vehicle, on the odd occasion they have also helped the emergency services rescue vehicle occupants.

“We try to support the fire service and ambulance crews as best we can,” explains Werner Huber. Like on 10 August 2004, when the pair were on the scene of a serious bus accident in Dürrnberg with their recovery vehicle. Arrived at the location, they also helped rescue the injured. Many of them were stuck under or still within the overturned bus wreckage. For the most part, though, the duo’s bread-and-butter recovery work involves harmless technical defects. Nevertheless, accidents as the reason for them turning out from the yard are more the rule than the exception.

“Predominantly, we are called to deal with rear-end collisions,” says Alex Kircher. “Every now and again, we are called out to accidents in tunnels or massive pile-ups.” In the thick of the chaos, they have to quickly analyse the extent of the situation: what needs doing and how best can it be achieved? Which of the vehicles involved in the accident needs recovering first? How should they be raised or towed? Is it better from the front or the rear end? The decisions are not always easy to make. The two professional recovery agents make their decisions based on their experience of 16 and 20 years respectively, after having discussed the scenario with the emergency services on the scene. “The collaboration with the police and fire service is truly excellent,” says Alex Kircher. “That said, you still shouldn’t lose sight of the fact that every operation of this kind is an extreme situation.”

First and foremost, the first thing that has to be carried out is the rescue operation of the victims involved in the accident. Only once that is achieved can they turn towards recovering the crashed vehicle. And even that isn’t always a walk in the park. “Every accident is different,” continues Alex Kircher. Sometimes it involves bringing a truck back onto the road after it has skidded off-course or towing away an immobile vehicle. Other times, however, it involves raising a toppled piece of construction site machinery out between the trees on a steep, wooded drop before it can be put back upright on a narrow forest track.

“We have also already helped during a helicopter rescue operation, as well as with removing rootstock, or even with film shoots,” says Werner Huber. “That’s the interesting thing in our line of work. No day resembles another; we continually get confronted with new challenges and have to handle unusual situations, in which we have to think about how we can best accomplish the task at hand.”

If, like in this current case, the task is to recover an Actros of a Czech transport company which has suffered only minor damage following an accident, then the process is pretty much routine. Alex Kircher casts a checking glance across the vehicle involved in the accident and wants to bring it into the correct position for transport. To do this, he rolls his own four-axle Arocs back to just a few metres ahead of the Actros and then uses a remote control to fold out the recovery arm of the Empl EH/W Bison 200 body. The arm can be swung upwards by 6.8 metres and 3.6 metres out to the rear – today, all they need is just a few centimetres. Kircher reaches out to the hydraulic winches of the recovery arm, both of which have a 20-tonne tractive force. He then hooks them on to the front of the vehicle.

Meanwhile, Huber has positioned an Antos 2535 with platform body behind the damaged tractor unit, folded down the support arms and aligned the Palfinger 18002 crane. “If we raise both the front and rear at the same time, we can pretty much move the truck into any position we like,” explains Huber. That’s the reason the team virtually always drives out to operations in both the Arocs and the Antos when it concerns recovering accident-damaged vehicles. “We often have to put vehicles the right way up before transporting them,” says Alex Kircher.

Werner Huber (L) and Alex Kircher hook up the accident-damaged Actros of a Czech transport company – an easy case for both pros.

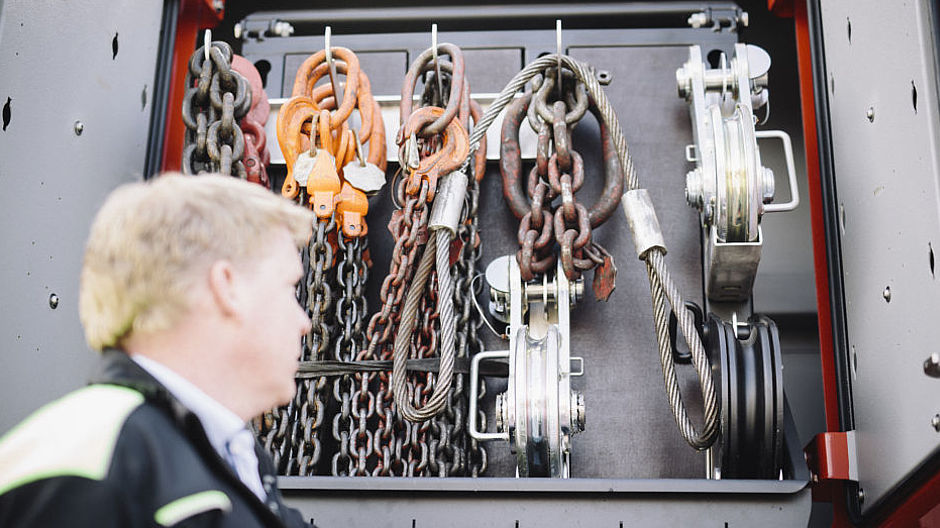

That won’t be necessary in today’s case. Kircher lowers the hydraulically-powered lifting yoke. To it, he can attach various attachments which are stowed away in the multifunction box on the side of the Empl body together with chains, pulleys, winches and spades. Kircher opts for the wheel lifts and pushes a button to draw the accident-damaged vehicle onto the lift using the winches. After that, he raises the truck using the lifting yoke. Job done!

“The Arocs is a top vehicle,” says Alex Kircher after finishing doing what he was doing. “We’ve only had it in operation for a week now, but we’re already really impressed with it.” Particularly advantageous compared with the previous vehicle is the turbo retarder clutch, which shows its true strengths in off-road terrain. “Even under full load, it means we can pull away without wear and tear. During recovery operations, that’s far more important than high engine output. Power is available even in the low rev range and is transferred immediately and directly to the road.”

The retarder also assists the driver thanks to its high braking potential. That applies both at low road speeds as well as when reversing. Wear-free operation also increases the vehicle’s availability over the long term. It’s not the only reason why Erwin Pfeiffer, Head of Operations at Pappas Eugendorf, is impressed with the new Arocs – which incidentally also happens to be the only all-wheel drive recovery vehicle in Salzburg. “This vehicle has already put is in a very good position,” he says, looking at Kircher and Huber. “But you also need the right people for the job in order to make the most of its strengths.”

Photos: Matthias Heschl

Comment

Please log in to post a comment.

No comments yet