Franz Hartl transports fermentation residues in his Actros

Vehicle & Technology

Franz Hartl transports fermentation residues for the Zellinger waste disposal company in Upper Austria. It was love at first sight when he received his new truck.

Franz Hartl was initially sceptical. The fact that he was due a new truck was pretty clear, but did it really have to be a Mercedes? A few months on and things look a lot different. Franz Hartl's beaming smile says it all. The driver from Upper Austria is happy for a number of reasons: firstly because of the choice of brand made by the company's boss, Jürgen Humer, then of course because he loves his job as a driver for the Zellinger from Mühlviertel, Austria, and last but by no means least because he's currently on the road in a very special vehicle: a brand new Actros 1848. Imagine that!

Driving at walking pace, Franz Hartl steers the truck into the immense cow shed on a farm near St. Peter am Wimberg. The Actros drives along the feeding alley which resembles a road. To its left and right, milk cows push their heads through the bars. They've never seen anything quite like this before: right in the middle of the farm, there it is, the flagship truck of the brand with the three-pointed star. And Franz Hartl is captaining it from within the cab.

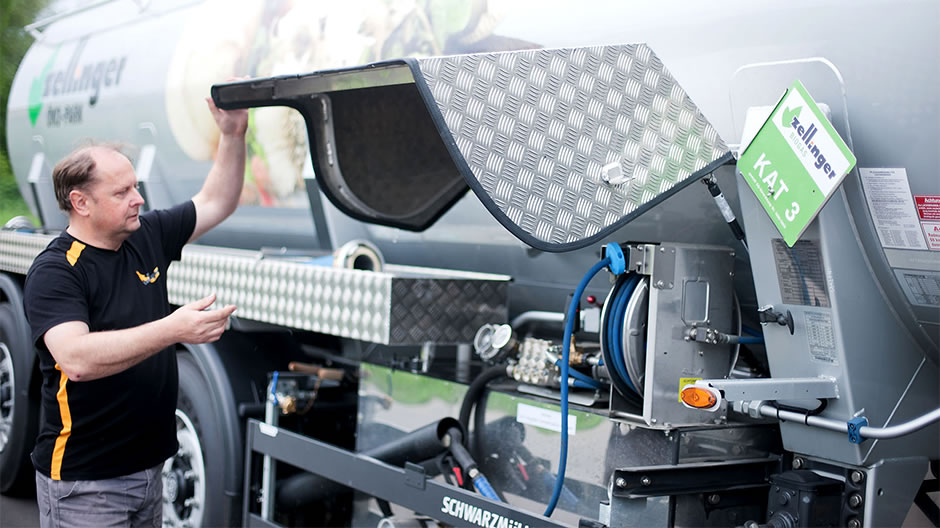

The new Actros tractor unit of Zellinger GmbH is used in a variety of ways – transporting fermentation residues in the tanker semitrailer is just one of them.

He takes a look in the mirror. There's not much space here and so Captain Hartl adjusts his speed accordingly. After reaching the halfway point of the building, he stops the vehicle, lowers the trailer off to the rear and jumps down from the cab. It's time to get hands-on and unload the hot cargo. Where others would scrunch up their nose, the Austrian remains well-spirited. It's not foodstuffs waiting to be unloaded from inside his three-axle tanker, it's liquid fermentation residues. This is formed as a bi-product of the disposal process during which food waste, out-of-date produce and feeds are turned into biogas at the biogas production plant where Hartl works.

Click here to leave RoadStars and to find out more information within Google Maps: Map on Google Maps

In the so-called Öko-Park (Eco Park) in Herzogsdorf, around 20 kilometres down the road in the direction of Linz, Zellinger GmbH and its 80-strong fleet (of which half bear a star on the bonnet) move organic and dairy farm waste, food waste and other organic waste into a transfer bunker. The material is broken up, freed from undesirable materials, diluted in the two preliminary troughs and put into temporary storage. Passing via the hygienisation unit, the prepared – and now liquid – material then moves into the supply tank, where it is mixed with substrate in order to start the fermentation process. It sounds complicated, but it's actually a simple chemical process from which biogas can be obtained. In two cogeneration plants, environmentally-friendly green electricity is produced. The fermented substrate is then transferred into special fermentation residue containers and, as it is an environmentally friendly alternative to chemical fertilizers, farmers are more than keen on taking delivery of this product.

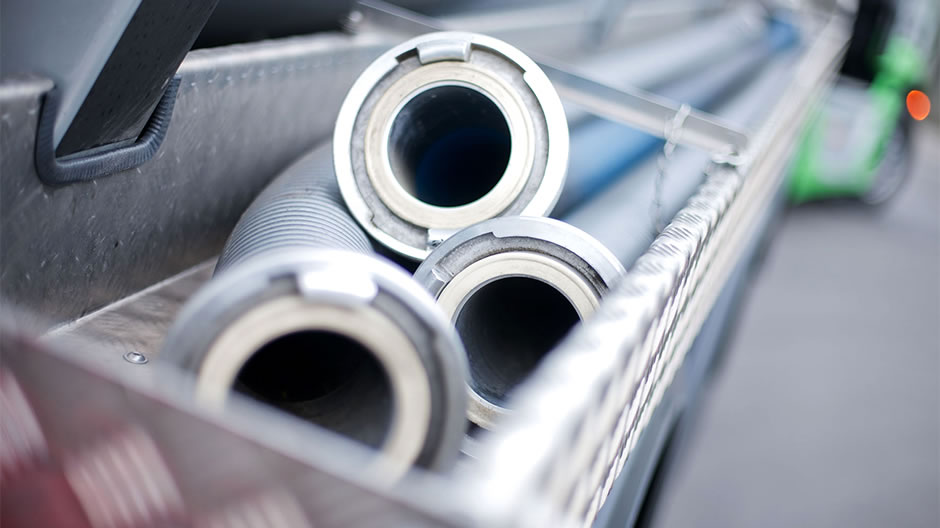

"For the farmer here in Mühlviertel, the liquid fermentation residue is more than that, though. He uses it to wash away animal excrement which gets stuck in the slurry channels under the split-level floor of the sheds. Fermentation residue is the right material for rinsing here," says Jürgen Humer. Meanwhile, Franz Hartl screws on an attachment to the filler neck of the tanker trailer. To it, he attaches the hose using a clip. A couple of seconds later, he releases the fermentation residues at the press of a button. Litre-by-litre, it seeps through the gaps in the ground and does the desired job underneath the floor: a powerful bit of cleaning.

Normally, Franz Hartl would pump his cargo into the 550-cubic-metre slurry tank outside the shed. "But what's most important is that the customer is happy," he says. And the driver? "At first, I was really very sceptical towards the Actros, but then it was like love at first sight. Already when I saw the truck for the first time, I was taken aback. When I got behind the wheel and drove a few miles in it, I was flabbergasted."

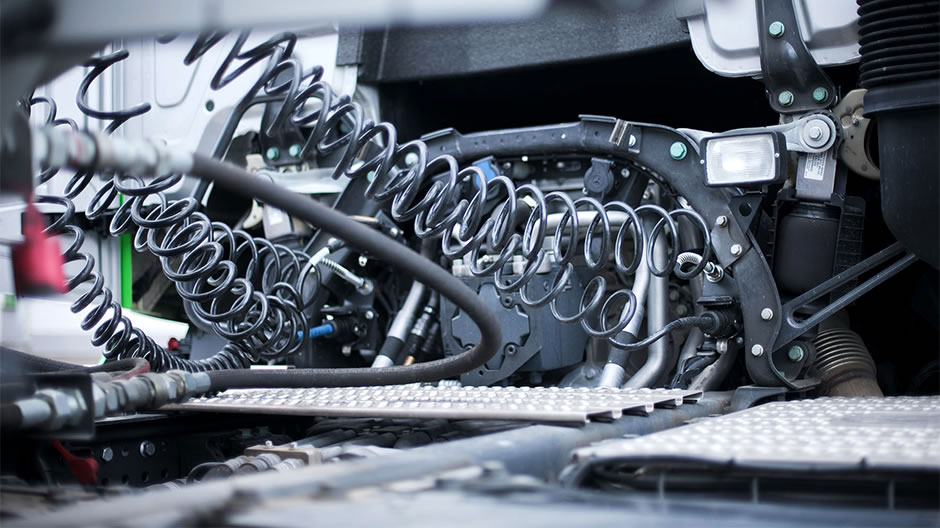

What was it that really convinced him? "The whole package," says Franz Hartl. "The Actros doesn't have any weaknesses: great workmanship, high ride comfort and impressive technology are all on-board. I can't fault it." What's particularly good about it? "The HAD system has also already impressed me. It gives me the advantages of an all-wheel-drive vehicle, without the associated disadvantages." The Hydraulic Auxiliary Drive is a selectable starting-off aid, which can provide additional tractive support whenever the driven axles threaten to lose grip. To formulate it in Franz Hartl's words: "It means I don't get left standing waiting for a tractor to come and tow me out of trouble."

Special treatment for the farmer – the fermentation residue from the biogas production plant normally gets pumped into the slurry tank, but it also makes for a great cleaning agent in the sheds.

Managing Director Jürgen Humer is also full of praise for the new arrival in his fleet: "Everything is spot-on – even from a business point of view. We're happy all round with it." Originally he didn't even want to buy a new tractor unit, preferring instead just a used trailer. "But the more we looked at the vehicle and its possibilities, the easier it was to make our decision. At the end of the day, the Actros has made us more flexible in our fleet planning. Where required, we just uncouple one trailer and couple up the next one, and then we're ready to tackle another field of our operations," says Jürgen Humer.

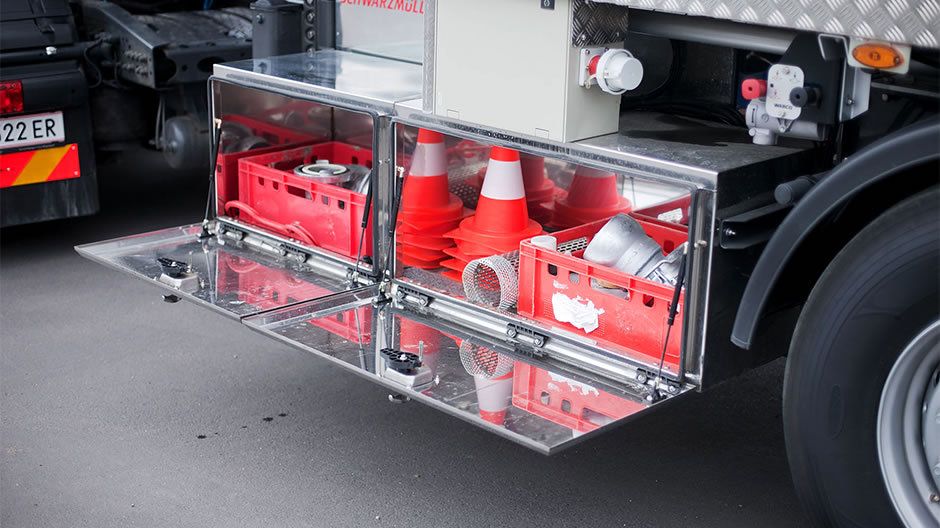

In the waste disposal industry, Zellinger GmbH is seen as a pioneer in the Upper Austria region. Also included in the broad range of services they offer are sludge dewatering, dredging, container rentals and general transport tasks. "Using our tanker, walking floor, tipper and palette semitrailers, we can be very flexible," explains Jürgen Humer. "What's more, due to our requirement to drive longer distances on motorways, it was also a massive bonus that the Actros is equipped ready for the Euro VI norm."

Here in the shed, the efficiency of the Actros drive system is a secondary issue. Spring is when fertilizing is carried out, and what matters then is the fermentation residue – the farmer could do with a few thousand litres more of it. "As soon as it runs out, you can pretty much set back out with the next delivery," says Franz Hartl in his broad Upper Austrian accent. Fine by him – there's nothing he likes doing more. Together with his Mercedes. Imagine that!

Photos: Bubu Dujmic

Comment

Please log in to post a comment.

No comments yet