Real horse power: the horse trucks from Böckmann are extremely popular with horse riders

Vehicle & Technology

Many equestrians swear by Böckmann horse trailers. But the flagships of the family-run company from Lower Saxony are undoubtedly the horse trucks based on the Actros or Atego. They are tested and further developed in the best possible environment: their very own stud farm.

With his brown coat shining in the autumn sun, Mackmyra gallops up and jumps the obstacle seemingly effortlessly. On to the next round! What looks so easy here, is the result of persistent training. “On average it takes a year for a horse of this breed to jump like this,” says Gilbert Böckmann after dismounting to give the five-year old Oldenburg horse a break. “Some are able to do this after seven months, but others take double that length of time. Every horse has its own character.”

“Each product must first prove itself at the stud farm. We only produce what is suitable for our own animals.”

– Klaus Böckmann

Klaus Böckmann (l.), Executive Manager at Böckmann Fahrzeugwerke GmbH; here with his brother Gilbert who holds the very same position at Böckmann Pferde GmbH.

Almost no one knows that as well as 59-year old Gilbert Böckmann. He has competed in the Nationenpreis and has also already won several tournaments in Europe, plus as a trainer he has trained even more horses to tournament level. As a trainer he also makes good riders even better, among which the Australian national team. The day before the meeting with the RoadStars team at his stud farm in Lastrup in the Oldenburger Münsterland region, he returned from a tournament in Spain where he participated both in the saddle and as a trainer.

In the horse truck to 40 tournaments a year.

Gilbert Böckmann and his team are always on the go: “We drive to up to 40 tournaments every year.” Regardless of whether they are travelling to Spain or France or to one of the many show jumping meets in Northern Germany, they always travel and live in a “true Böckmann”: a horse truck with species-appropriate boxes for the horses and a comfortable living area for the two-legged team members. Designed and manufactured at the Böckmann vehicle plant just a few kilometres from the stud farm.

Vehicles are produced for customers from all of the world there – for local professional and amateur riders, for horse logisticians and stud farm owners from the Middle East. “We produce about 100 horse trucks annually,” says Gilbert Böckmann's brother Klaus who runs the business. The vehicles can provide space for up to twelve horses and six people. They are the top products in a catalogue that also includes a variety of trailers – for horses but also much smaller variants for transporting garden waste and building materials.

The largest and most exclusive horse trucks have one thing in common: the Actros or the Atego serves as their basis. The vehicle that the stud farm uses for tournaments is an Actros. “For our 'Equipe' series we always only recommend Mercedes-Benz chassis to our customers,” says Klaus Böckmann. They have the robustness that the basis of a vehicle needs when several heavy horses weighing in at 600 kilogrammes each are on-board and inevitably move around.

This article contains additional material (videos, images and reports etc.) for registered RoadStars members. In order to experience the article to the full, you need to log in with your RoadStars account or register for one free of charge.

Become a RoadStar and gain access to exclusive content and campaigns!

Login for RoadStars members

Not yet a member? Join RoadStars now

Obtain exclusive access to exciting events and activities which only RoadStars can offer.

Join RoadStars“The chassis provide the ideal construction for every body,” the 61-year old tells us. “We also see this when we connect the body to the cab and then remove the rear wall of the base vehicle to open it up into a living area.” The production team uses the Mercedes-Benz Bodybuilder Portal to try and find answers to any questions that may arise.

The handling of the Actros and Atego also speaks in favour of the two models – and the same is true of their reliability too. And if a horse truck does ever break down, you know that you can always rely on the Mercedes-Benz service network that stretches across all of Europe! “Getting help fast is particularly important because we are transporting live freight,” says Böckmann. Another important factor is the positive appearance of the trucks with regard to design. “For customers from equestrian sports a product doesn't need to just function perfectly, it has to look good too!”

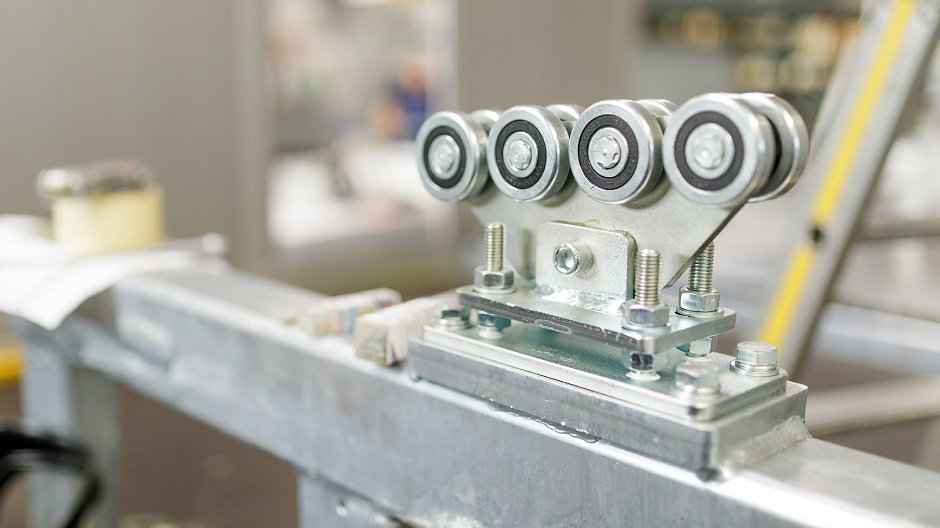

The RoadStars team gets to see just how much care goes into producing the trucks in hall 13 of the vehicle production plant. The sparks are flying from the welding equipment of two workers bent over a skeleton made of high-strength steel: the support frame for a truck based on an Atego which will be hot-dip galvanized once it is finished. Close by, a colleague has a cordless screwdriver which he is using to secure a window frame in the roof section of a body for an Actros. “The slogan we use for our horse trucks is 'Handmade in Germany' and we live by that principle!” says Klaus Böckmann.

The biggest challenge when designing bodies is to give them maximum stability. “Because it is not only the movement of the horses that has a negative effect on this aspect, but also the openings in the body, i.e. the rear and side ramp as well as the windows.” This is combated by using high-quality materials – profiles made of anodised aluminium for the walls, aluminium floors, stainless steel panelling – and a focus on top-quality craftsmanship. This is also crucial when building the horse boxes. For example, there can be no sharp edges in them.

On average it takes 20 weeks for a horse truck based on an Actros to be completely finished.

Böckmann horse trucks are unique items. This is even more clear inside the living area than it is in the horse area. “Here we can implement everything that is available in the high-end camper van segment to suit the customer's wishes,” says Klaus Böckmann. The basic living space or a bay that extends from the side of vehicle, underfloor heating or infra-red wall heating, surfaces made of wood or real leather, huge refrigerators or even a PlayStation – there are hardly any limits to the possibilities. “We plan everything together with the customer and then a furniture company takes care of the construction.”

At present the stud farm has two horse trucks on the basis of an Actros and one that is built on an Atego. Not only do Gilbert Böckmann's riders and stable hands benefit from this but also the vehicle builders – and in turn the customers. “Each product must first prove itself at the stud farm. We only produce what is suitable for our own animals,” Klaus Böckmann explains. If the team discovers room for improvement during their everyday routine, they pass this on to the production department. “This underlines our own guiding principle: we develop vehicles based on practical use for practical use.”

One name, two businesses.

The name Böckmann stands essentially for two sister companies which turned over 85 million euros last year. Böckmann Fahrzeugwerke GmbH contributes the greater share of that. It employs a total of about 500 people in Lastrup at two locations – one of them as part of a joint venture. In addition to around 100 horse trucks, approximately 20,000 trailers are manufactured annually – many of them for horses. In Lastrup, Böckmann Pferde GmbH has just under 20 employees who care for around 200 animals of which 50 are their own.

The stud farm has four areas: in the show jumping and tournament yard the horses and riders are trained. There is also a stud ranch with the sale of frozen sperm and a breeding station for foals and two and three-year olds. The fourth area is the dressage stables which is under lease by a Portuguese Grand Prix rider. The company began as a farrier and blacksmith business for horse-shoeing and repairing agricultural machines and was managed by Anton Böckmann, the father of the two present managing directors. He bought a Shetland pony called Raudi for his four sons, laying the foundations that would lead to the name Böckmann being associated with equestrian sport for decades to come.

Photos & video: Jan Potente

Comment

Please log in to post a comment.

16 comments

Was für ein Betrieb.

Alle Achtung vor dieser Verantwortung. Ich wünsche weiterhin viel Glück und ein gutes Händchen.

Was für ein Betrieb.

Alle Achtung vor dieser Verantwortung. Ich wünsche weiterhin viel Glück und ein gutes Händchen.

Hab leider noch kein Horse Trucks gesehen aber viele Anhänger...jetzt bin ich schlauer wer oder was ""BÖCKMANN "" ist.

Viele Grüsse an das BÖCKMANN Taem.

Hab leider noch kein Horse Trucks gesehen aber viele Anhänger...jetzt bin ich schlauer wer oder was ""BÖCKMANN "" ist.

Viele Grüsse an das BÖCKMANN Taem.

P.S. I also saw their products based on FIAT van 🤦🙀👿👹👺

P.S. I also saw their products based on FIAT van 🤦🙀👿👹👺

LG.

Udo

LG.

Udo

Gruß

Klaus

Gruß

Klaus