Real-life test: Hydraulic Auxiliary Drive (HAD) starting-off aid

Vehicle & technology

The Hydraulic Auxiliary Drive (HAD) starting-off aid offers additional traction when needed – and its added weight is practically negligible on long journeys. Karl Fischer GmbH, which operates more than 20 Arocs trucks, has already tested the new system.

This is one of those mornings you want to be over with as quickly as

possible. Like a grey veil the rain covers the gravel plant in

Erkenbrechtsweiler on the Swabian Alb. It has been going on like this

for hours with no end in sight.

And to make things worse, to make room for an oncoming dump truck, Bernd Schweizer in his Arocs 1848 has to pull over onto the muddy roadside while going up a hill. He anxiously looks at the rain-soaked track ahead of him while the huge tyres of the tipper as tall as a house roll by his window. Will the tyres be able to maintain traction on the muddy track? "Now the system can show what it is capable of", says the 54-year-old. As he starts to accelerate, a blue symbol lights up on the display – the indicator for the Hydraulic Auxiliary Drive (HAD).

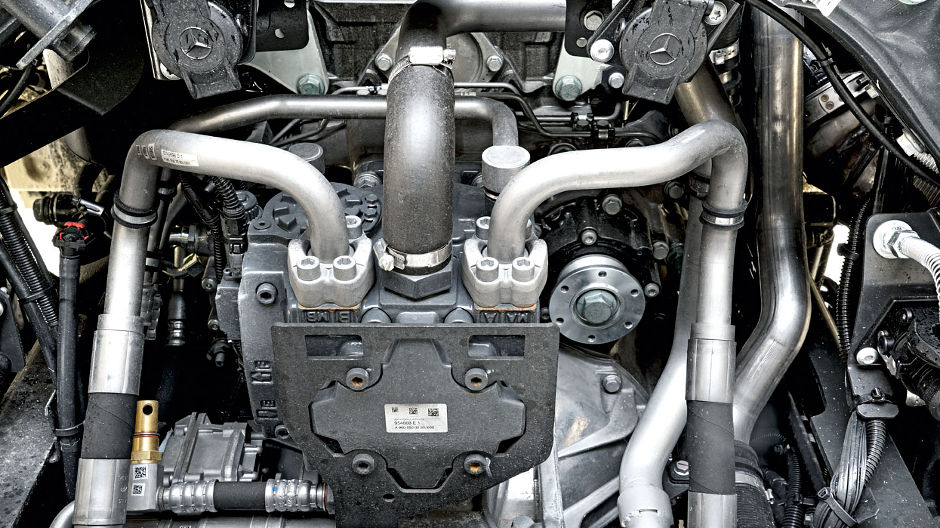

He activated the system upon entering the gravel plant with a switch on the dashboard. The high-pressure pump mounted to the engine now sends up to 450 bar of pressure to the wheel hub motors on the front axle. The pressure pushes hydraulic pistons outward, which in turn drive the cam ring. This creates an additional 40 kW of drive power at each wheel.

Bernd notices none of these things. The only thing he feels is that the front axle is now also involved in propelling the truck forward. This creates additional traction. And as a result, Bernd makes it effortlessly up the hill.

"The difference such a switch can make is truly

impressive!", says Schweizer. Joachim Schmid, his boss and

managing director of Karl Fischer GmbH, can only agree. His company

was the first to put the new system through its paces as part of

customer field trials.

The around 100 trucks that Fischer operates are used predominantly

in bulk material transport. "For example, we load rock from the

gravel plants on the Swabian Alb. For this job the added traction is

very useful to us on the frequently muddy and steep access

roads", Schmid says.

The trip to the unloading station, on average about 100 kilometres

away, most often leads over well-maintained country roads and even

motorways. That is why Fischer needs an optimal powertrain with

Mercedes PowerShift 3 and maximum payload.

When the Daimler development engineers inquired whether Schmid wanted to test the new hydrodynamic front-wheel drive, he didn't hesitate for a second. "It seems to have been made just for us!" That is because the Hydraulic Auxiliary Drive combines the advantages of all-wheel drive with those of a classic drive system. As a supplemental traction booster, HAD delivers just as much additional power to the front axle as needed – up to 40 kW per wheel are possible. HAD boosts traction up to a speed of 25 kilometres per hour. All the driver needs to do to activate the system is to push a switch on the dashboard. "But it is also important that the driver gives input via the accelerator pedal. This is the only way the system knows how much traction is required", says Detlef Schnitzer, HAD development project manager. The Daimler engineer and the team for the customer field trials have kept in close contact with Fischer Company during the test run. "We get important feedback from real life as a result".

For example, how the hydraulic pump, the centrepiece of the new system, operates under extreme conditions. The pump is one of the special features of HAD. Because contrary to other products on the market, it is not mounted on the transmission, but on the engine PTO. "As a result, HAD's full tractive force is maintained during gear changes. And there is still space left on the transmission for a retarder", says Schnitzer.

A further advantage of the system: HAD weighs 350 kilograms less than on-demand all-wheel drive and 500 kilograms less than permanent all-wheel drive. In addition, there is no rotating drive axle that increases fuel consumption. Fuel savings of up to eight percent over the all-wheel-drive variants are possible. "Our vehicles drive about 100,000 kilometres a year on average. Every litre of fuel we save is worth its weight in gold", says Schmid. The managing director of Fischer Company has always been a true Arocs fan. "Its power, robustness and efficiency make it the perfect vehicle for our jobs", he says. He bought 19 new Arocs trucks this year alone. In the past, all were equipped with on-demand all-wheel drive. "But from now on there will definitely be one or the other with HAD among them".

Click here to leave RoadStars and to find out more information within Google Maps: Map on Google Maps

HAD – the advantages.

HAD is suitable for all operations which temporarily require maximum traction but also demand a high payload and an optimal powertrain.For example, in the case of tipper semi trailers, lumber trucks or snow ploughs. HAD is available for the OM 470 and OM 471 engines in the Actros, Arocs and Antos.

- The high-pressure pump's position on the PTO has the advantage that the full tractive force is available even during gear changes. In addition, there is still space left on the transmission for a retarder. In conjunction with the OM 471 engine, HAD is also available with a PTO.

- Hydraulic rotary distributors in the axle stubs prevent twisting of the hydraulic lines and ensure a long service life.

- The side-mounted cooling system with a capacity of 20 kW ensures that HAD is available even for extended periods of time at speeds of up to 25 km/h. The oil filter does not need replacing until after about 600,000 kilometres.

- The advantage in terms of weight of 350 and 500 kilograms, respectively, over on-demand and permanent all-wheel drive increases the payload. In addition, fuel consumption is reduced.

- Available with

Mercedes PowerShift 3.

Photos: Matthias Aletsee

Lean on the road. HAD makes fuel savings of up to eight percent possible compared with other all-wheel-drive systems. Consequently, investing in the on-demand starting-off aid can pay for itself in as little as about two years.

Comment

Please log in to post a comment.

No comments yet